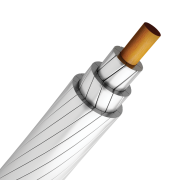

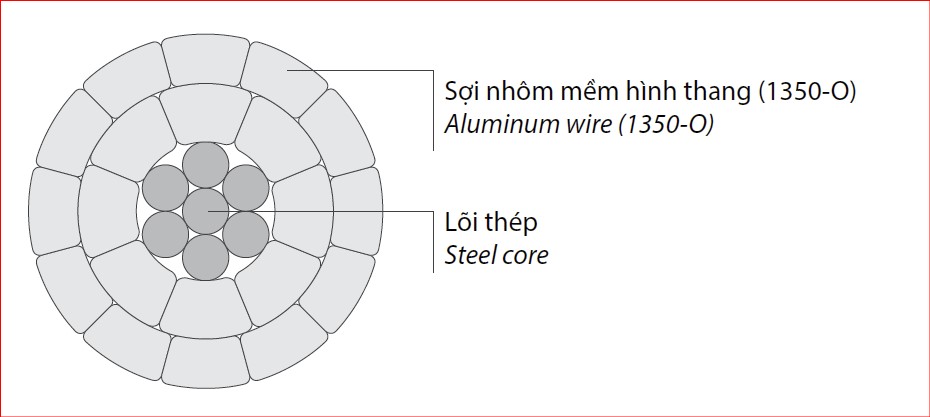

TRAPEZOIDAL ALUMINUM CONDUCTORS, COATED STEEL SUPPORTED

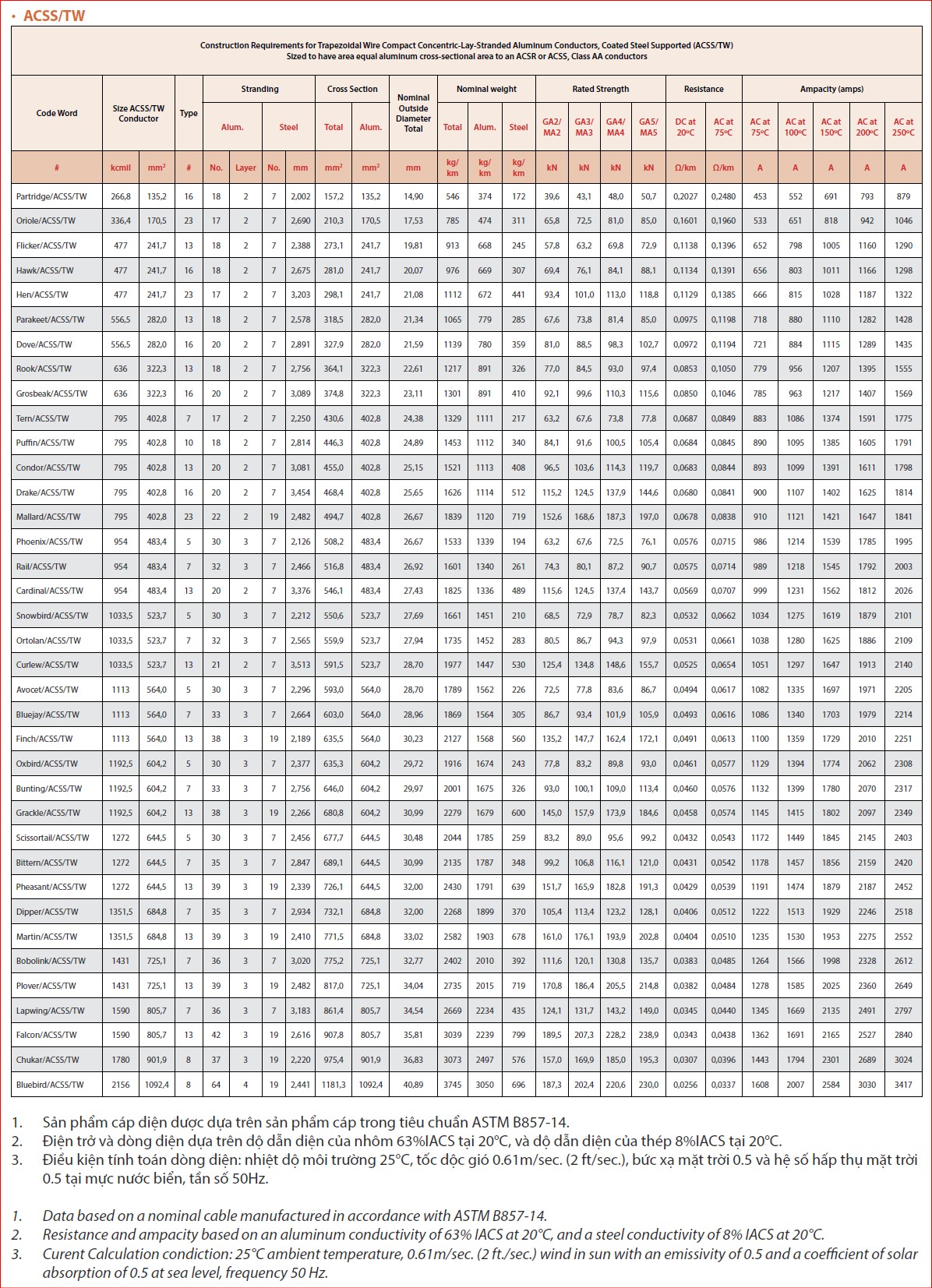

ACSS/TW

Standard: ASTM B609, ASTM B502, ASTM B498, ASTM B802, ASTM B803, ASTM B606, ASTM B957, ASTM B958, ASTM B857.

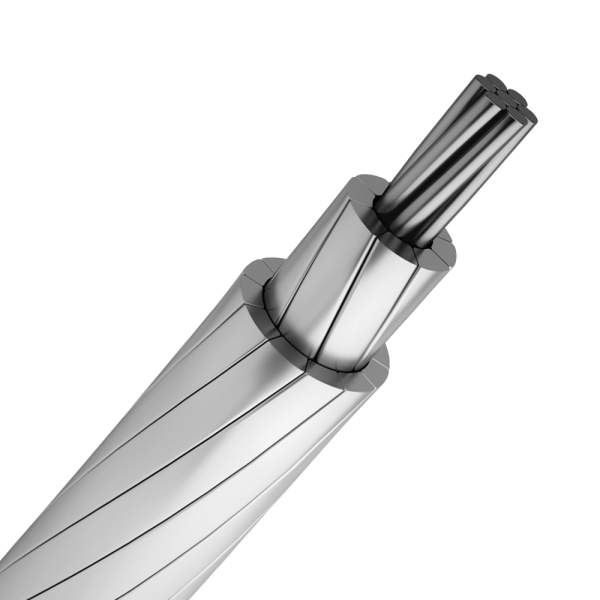

Construction:

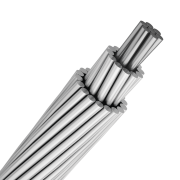

- ACSS/TW is a trapezoidal aluminum wire compact concentric-lay-stranded conductor. Steel strands form the central core of the conductor with one or more layers of 63% minimum conductivity aluminum 1350-O wire stranded around it. Steel core wires are protected from corrosion, zinc-5% aluminum-mischmetal alloy coating, Standard, High, Extra, Ultra High Strength steel and aluminum clad steel core are also available.

Features and benefits:

ACSS/TW conductors are similar to conventional ACSR/TW conductors but have some very important additional advantages.

- ACSS/TW conductors can operate continuously at high temperatures(250°C) without damage;

- Its sags less than ACSR/TW under emergency electrical loadings;

- It has self damping properties;

- Its final sags are not affected by long-term creep of the aluminum.

- ACSS/TW conductors constructed of equivalent aluminum crosssectional area provide a conductor that is smaller in overall diameter than the equivalent conventional round wire ACSS conductor. The reduced conductor diameter is advantageous in reducing the effects of ice and wind loading on the conductor.

- ACSS/TW conductors constructed to equivalent overall diameter enable a greater cross-sectional area of aluminum within the conductor, allowing a significant increase in conductor currentcarrying capacity.

APPLICATION:

– ACSS/TW is designed for overhead distribution and transmission lines. It is designed to operate continuously at elevated temperatures up to 250°C without loss of strength, it sags less under emergency electrical loadings than ACSR/TW, excellent self-damping properties, and its final sags are not affected by long-term creep of aluminum.

– ACSS/TW is available in equal area and equal diameter design. The equal area design allows equal ampacity in a smaller diameter conductor when compared with a standard ACSS conductor. The equal diameter design allows more ampacity in an equal diameter conductor when compared with a standard ACSS conductor.

– ACSS/TW also provides many design opportunities for new line construction: i.e., reduced tower cost, decreased sag, increased self-damping properties, increased operating temperature and improved corrosion resistance.

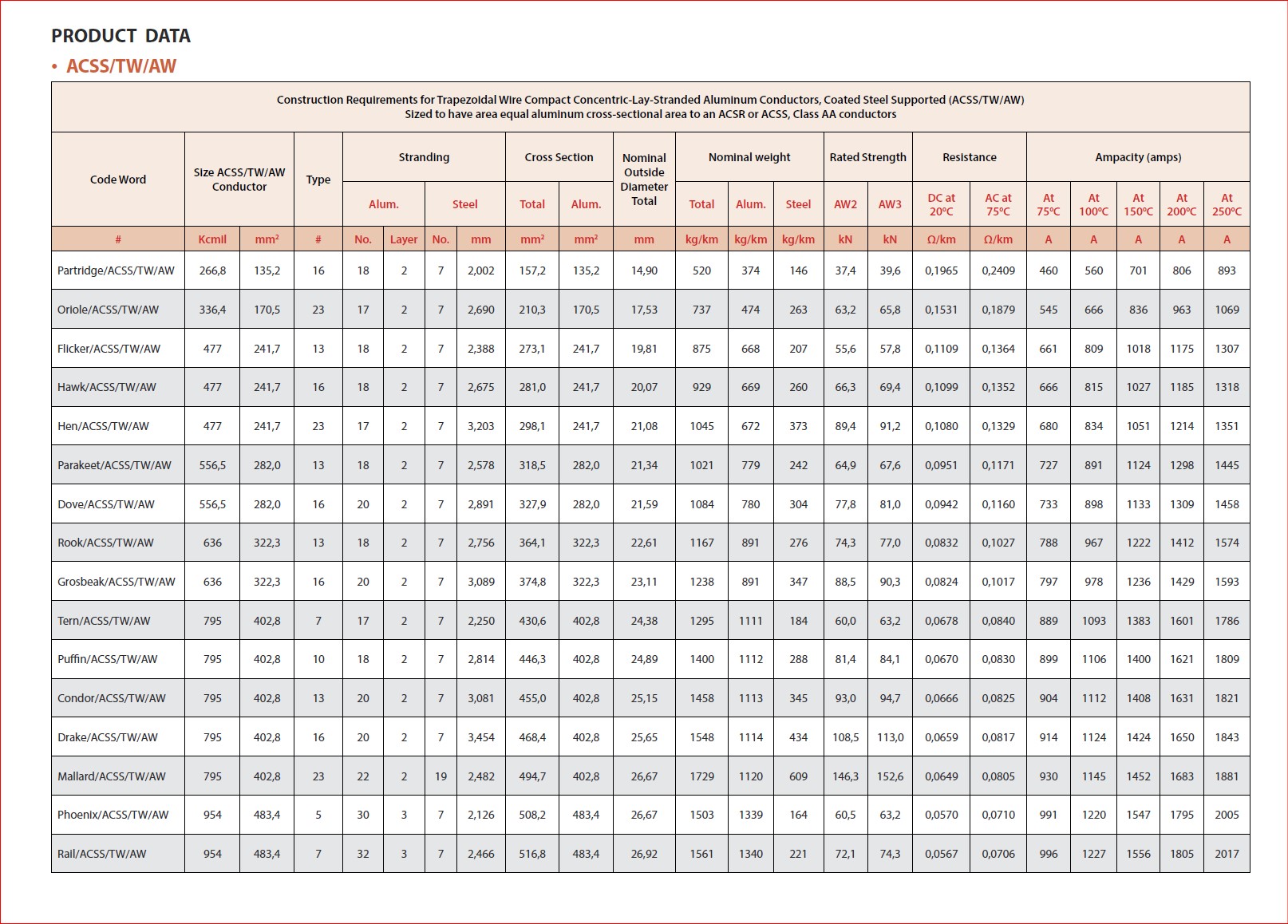

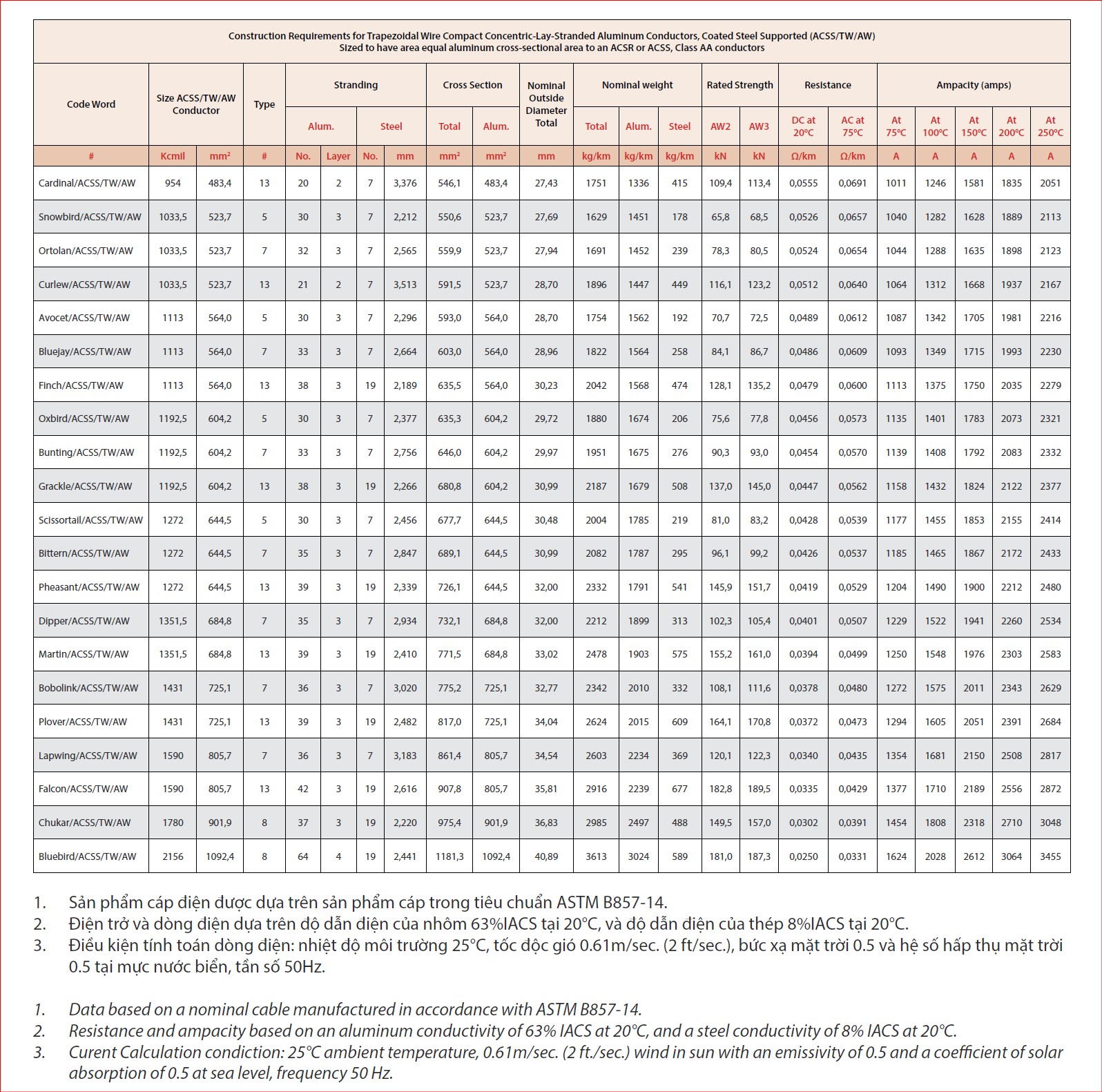

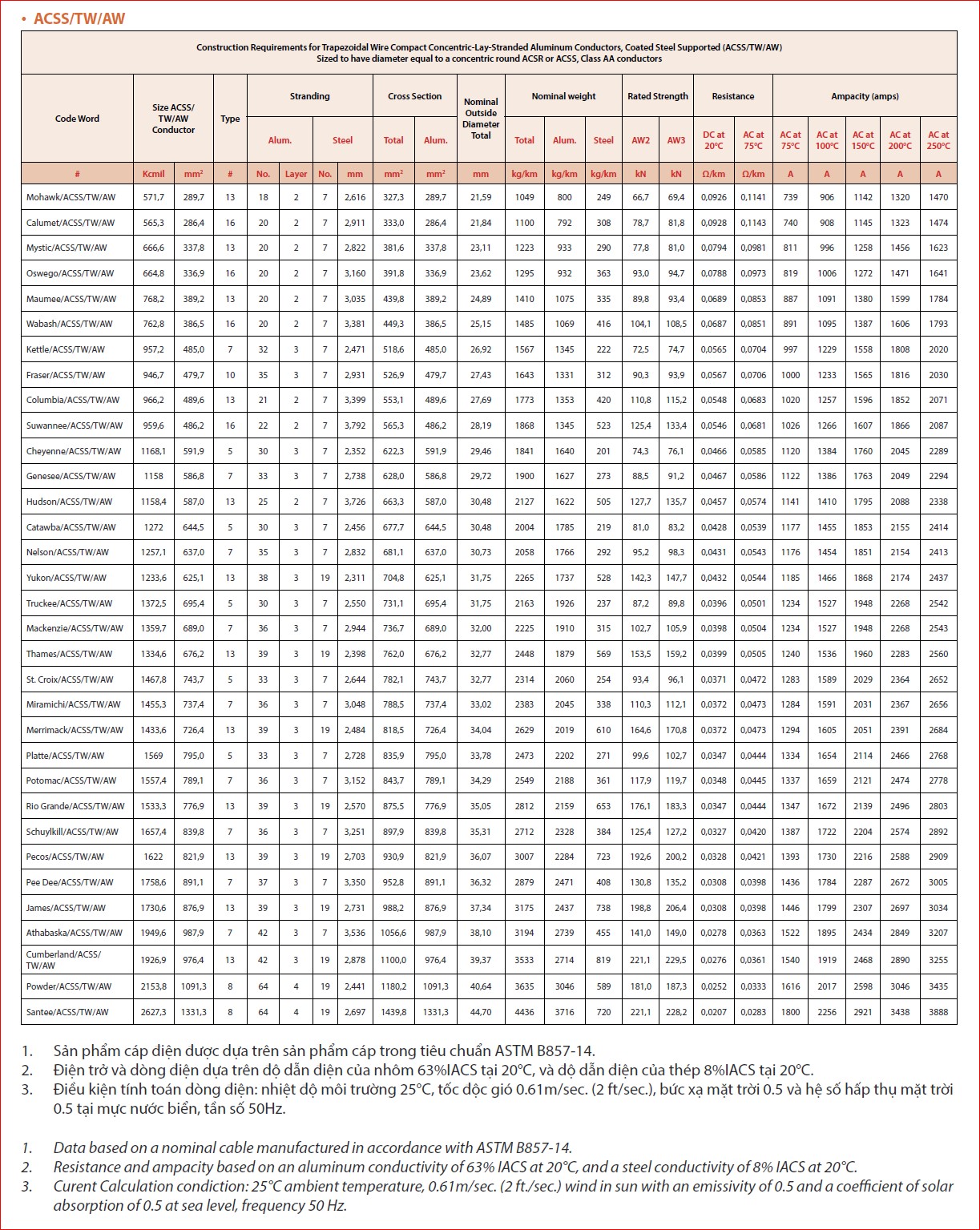

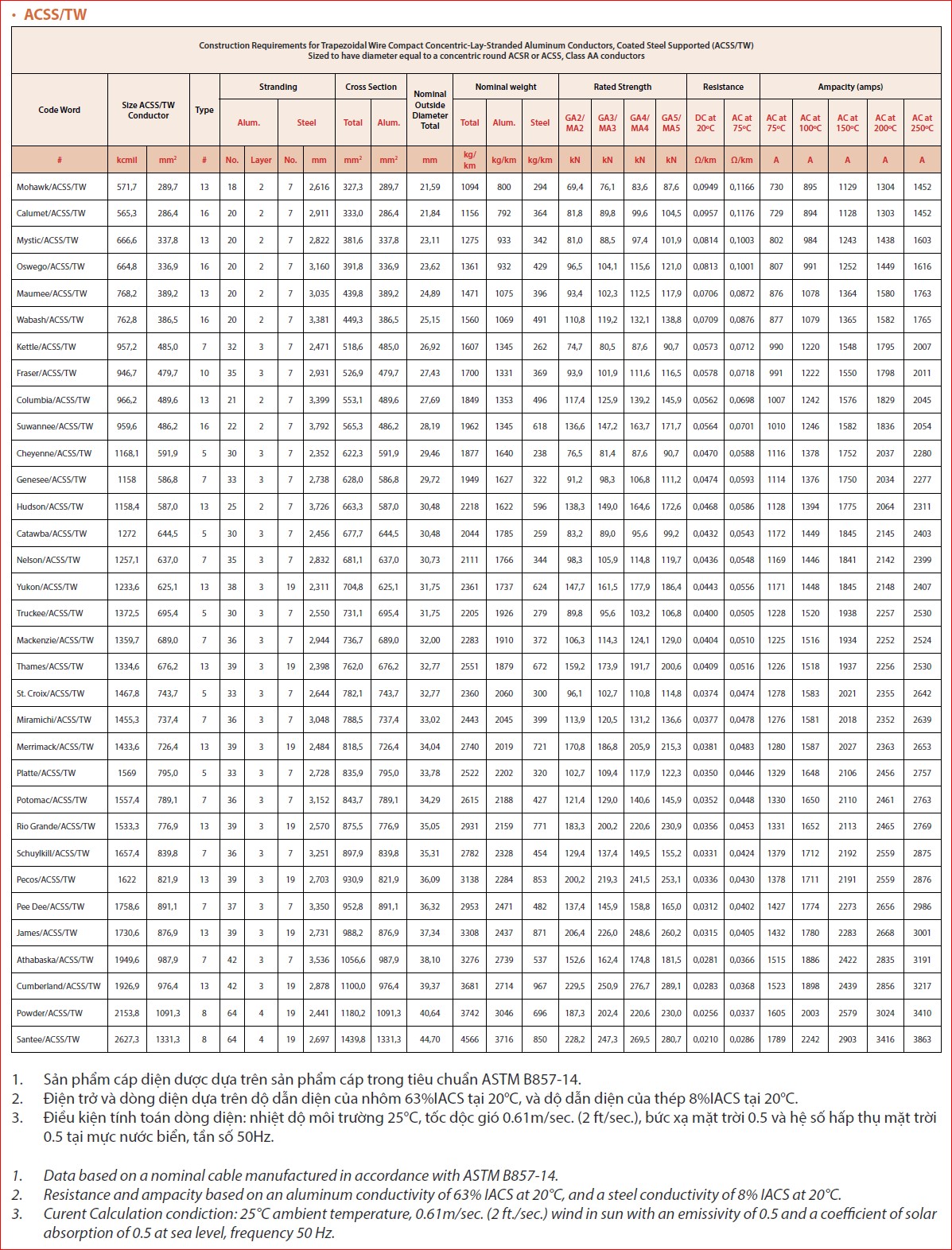

TECHNICAL INFORMATION OF PRODUCTS