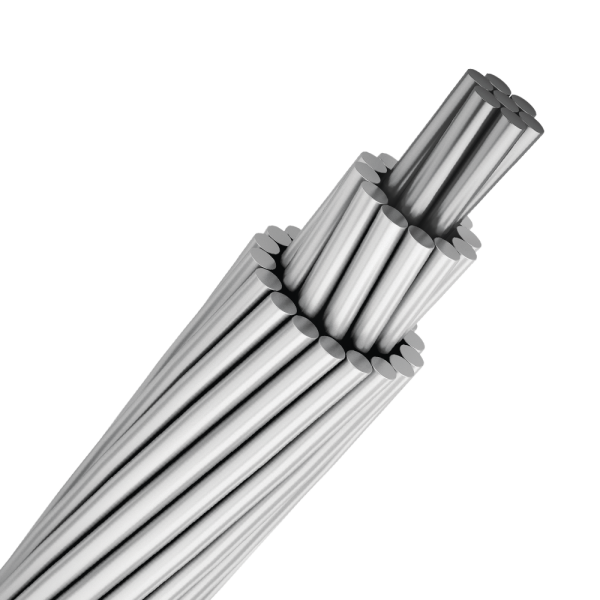

Thermal resistant aluminium alloy conductor, steel reinforced

TACSR & TACSR-G

Standard:

JEC 3406-95

Constuction:

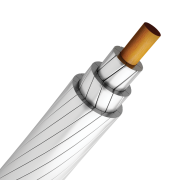

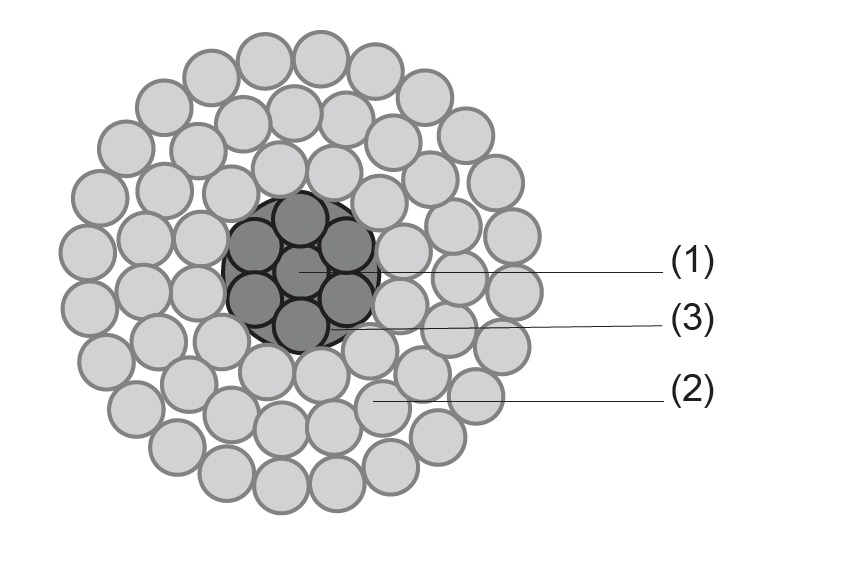

(1) Steel part: Zinc- coated steel wires (St)

(2) Aluminium part: Thermal resistant aluminum alloy wires (TAL), concentric stranded

(3) Grease part: Neutral grease (G), this is optional part and according to IEC 61089.

APPLICATION:

TAAAC used for overhead power transmission lines.

TECHNICAL INFORMATION OF PRODUCTS:

| Nominal area cross section | Structure [number x diameter of wire] |

Calculation area cross section | Approx. diameter of conductor | Min. breaking strength | DC resistance of conductor at 200C | Approx. mass of conductor | Current carrying capacity | ||||

| TAL | St | TAL | St | ||||||||

| mm2 | n | mm | n | mm | mm2 | mm2 | mm | kN | Ω/km | Kg/Km | A |

| 120 | 30 | 2.30 | 7 | 2.30 | 124.6 | 29.1 | 16.10 | 52.8 | 0.2370 | 573.1 | 605 |

| 160 | 30 | 2.60 | 7 | 2.60 | 159.3 | 37.2 | 18.20 | 68.4 | 0.1850 | 732.8 | 706 |

| 200 | 30 | 2.90 | 7 | 2.90 | 198.2 | 46.2 | 20.30 | 86.9 | 0.1490 | 911.2 | 818 |

| 240 | 30 | 3.20 | 7 | 3.20 | 241.3 | 56.3 | 22.40 | 99.5 | 0.1220 | 1,110.0 | 933 |

| 330 | 26 | 4.00 | 7 | 3.10 | 326.7 | 52.8 | 25.30 | 107.2 | 0.0904 | 1,320.0 | 1129 |

| 410 | 26 | 4.50 | 7 | 3.50 | 413.5 | 67.3 | 28.50 | 136.1 | 0.0714 | 1,673.0 | 1324 |

| 520 | 54 | 3.50 | 7 | 3.50 | 519.5 | 67.3 | 31.50 | 153.5 | 0.0568 | 1,968.0 | 1502 |

| 610 | 54 | 3.80 | 7 | 3.80 | 612.4 | 79.4 | 34.20 | 180.0 | 0.0481 | 2,320.0 | 1680 |

| 680 | 45 | 4.40 | 7 | 2.90 | 684.2 | 46.2 | 35.10 | 152.9 | 0.0431 | 2,260.0 | 1787 |

| 810 | 45 | 4.80 | 7 | 3.20 | 814.3 | 56.3 | 38.40 | 180.9 | 0.0363 | 2,700.0 | 2007 |

| 1160 | 84 | 4.20 | 7 | 4.20 | 1,163.8 | 97.0 | 46.20 | 273.8 | 0.0254 | 3,996.0 | 2594 |

| 1520 | 84 | 4.80 | 7 | 4.80 | 1,520.0 | 126.7 | 52.80 | 357.8 | 0.0195 | 5,222.0 | 3073 |